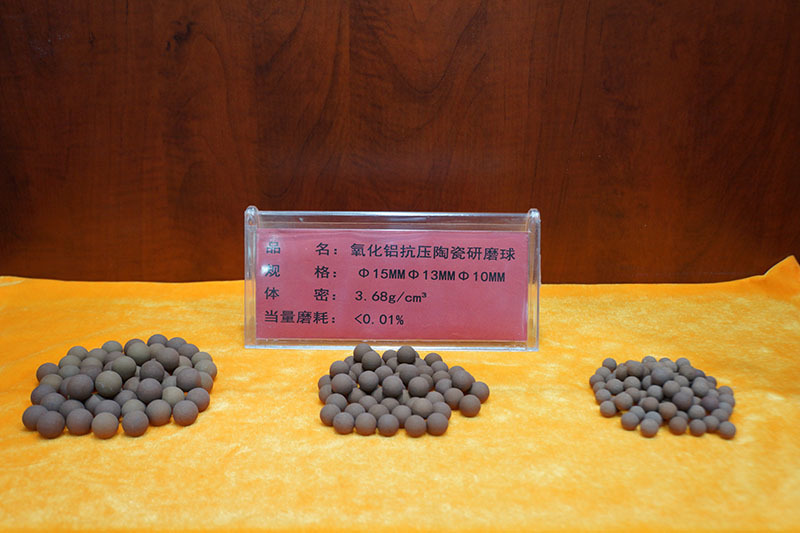

Compressive ceramic wear ball

Key words:

Compressive ceramic wear ball

Classification:

Product Description

The company has invested abundant capital and technical force to develop a new generation of high-strength ceramic grinding balls, which now reach 70T per day, which solves the shortcomings of low strength and brittleness of traditional ceramic balls, and makes ceramic grinding better in the cement industry. It has a significant effect on reducing energy consumption and saving costs.

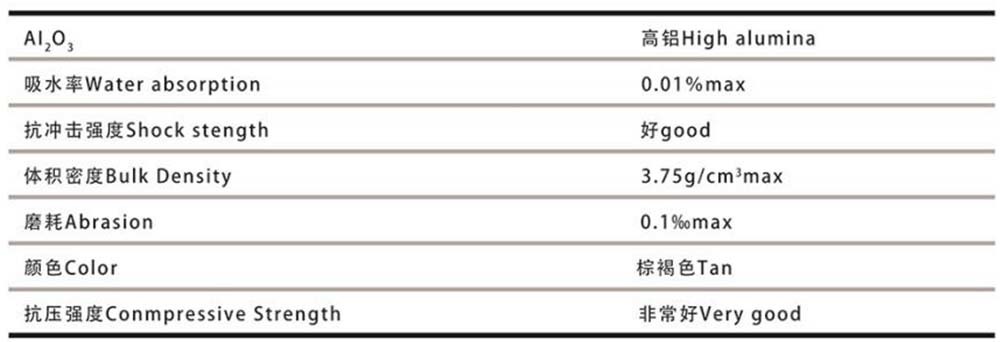

chemical and physical properties

Advantages of using ceramic balls in the cement industry

1. Energy saving and consumption reduction: the current of the main machine of the mill is reduced by more than 20%, and the electricity saving per ton of cement is more than 15%.

2. Improve the quality of cement products: improve the performance of cement, the particle gradation is more reasonable, the content of 3-32 micron particles is increased by more than 2 percentage points, the sphericity of particles is improved, the water consumption of standard consistency is reduced by 1-2 percentage points, and the cement is more suitable for concrete admixtures. 3. Cooling and noise reduction: The temperature in the mill is lower than 20 degrees Celsius, and the noise of the mill is reduced.

4, reduce electrostatic generation: greatly reduce the generation of static electricity, reduce the powder on the ball stone package phenomenon.

5. The wear resistance is better. The wear of microcrystalline high-strength wear-resistant ceramic grinding balls is less than 50% of steel balls.

Environmental protection: The water-soluble hexavalent chromium content in cement products is limited to 10 mg/kg(gb31893-2015), which is more conducive to green production.

7, the country to eliminate excess capacity, product transformation and upgrading of the general trend.

8. Reduce costs, save energy and increase market competitiveness.

9, reduce the harm of heavy metals, green environmental protection, improve the environment.

Compressive ceramic wear ball

Product inquiry

Related Products

Zhongxin New Material